MMS is short for ‘Manufacturing Management System‘. MMS by Kon-Cept is a solution that allows all information processes on the shop floor to be implemented electronically. It was specifically designed for use in the automobile industry, with a focus on line production that contains a high number of variants such as the final assembly of vehicles, final treatment, body shop and preassemblies.

MMS by Kon-Cept was developed by Kon-Cept in 1998. Today, the third generation of MMS is implemented in a large number of production facilities. MMS by Kon-Cept is a standardized product that incorporates many best practices, is highly configurable and thus can be adapted easily to the demands and processes of widely different OEMs and tier-1 suppliers. MMS by Kon-Cept has been designed as open system for smooth integration into a customer’s existing IT environment.

MMS by Kon-Cept has already been used to build more than 17 million vehicles by various OEMs. It has proven itself in daily operation, covering all relevant information processes in production, quality management and logistics on the shop floor. MMS by Kon-cept offers a high level of scalability and is used in productions operations with widely different quantity structures. These structures range from simple part assemblies at the tier supplier level, to managing entire production plants. Many implementations of MMS by Kon-Cept are mission critical, meaning that a failure of the system would result in a standstill of the production that must be avoided at any cost. MMS by Kon-cept is the result of long-time experience in the operation of highly critical systems. This is mirrored in the system structure e.g. as redundant hardware structure, in mechanisms for logging and monitoring as well as in algorithms and procedures that tolerate errors.

To complement its services, Kon-Cept offers consulting and helps with building a support organization. As we have a variety of capabilities at our disposal, we are in a position that lets us operate even the most complex installations with extremely high availability and reliability.

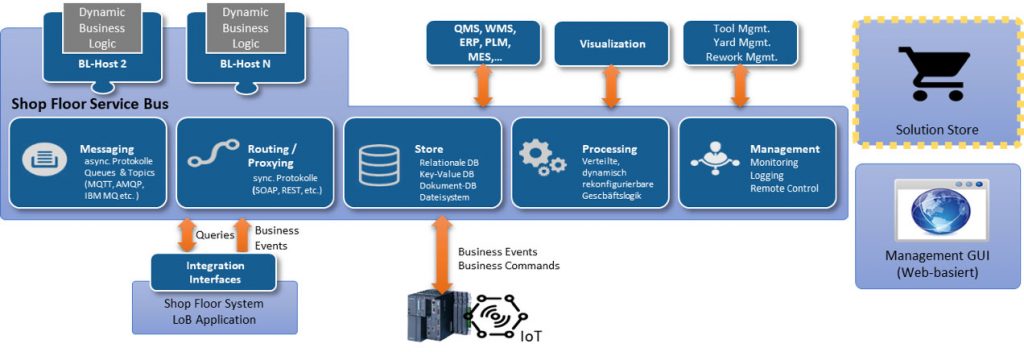

MMS by Kon-Cept as a shop floor IT solution is a hub for the real-time exchange of data between IT systems and machines on the shop floor. This role as a message hub is gaining importance as electronic data exchange in modern productions continues to increase. MMS by Kon-Cept accommodates this requirement by using a Shop Floor Service Bus as its basic communication platform. The platform consists of two components: a messaging backbone and a business logics host.

The Shop Floor Service Bus organizes and simplifies the launch of complex plants that have a large number of communication interfaces. Sender and recipient within conversations are separated, making change management easier. Data exchange is configured, logged and monitored centrally.

Hosting a distributed business logic enables MMS by Kon-Cept to have a distributed, redundant and highly scalable system structure. It is possible to easily extend the Shop Floor Service Bus through new business logics components and new data interfaces any time, thus allowing MMS by Kon-Cept to adapt seamlessly into every IT environment. A central solution store enables the efficient application of a central governance paired with maximum flexibility when projects are realized.