MMS by Kon-Cept is flexible and offers solutions for a wide variety of production issues.

Kon-Cept is continuously developing MMS by Kon-Cept by incorporating learning and findings from the projects of over 20 years. Together with our customers we have created and successfully implemented a catalog of solutions for Production and Logistics based on MMS by Kon-Cept.

Digital factory

Our MMS by Kon-Cept planning tools let you create and manage a virtual model of both the workshop and the product. MMS by Kon-Cept is a shop floor system that manages the ´real´ factory and thus is one of the main components of the digital factory. MMS by Kon-Cept enables the distribution of planning data obtained directly to every last corner of the production. Changes in the product, the product mix and resources can be implemented in the real factory in a very fast and transparent way, resulting in a significant increase in agility of production. Thus, product start-up phases can be reduced by 50%.

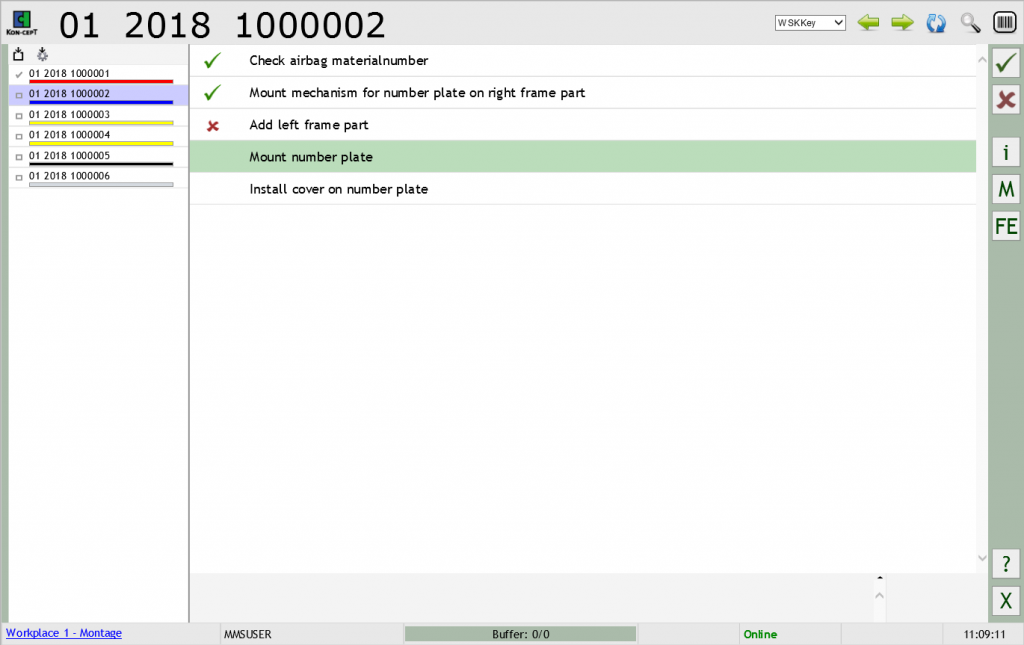

Electronic part documentation

The electronic part documentation supports the worker in the line by displaying the assembly information for a specific vehicle and the worker’s work place, relieving the worker from having to decode the paper build documentation. The electronic part documentation of MMS by Kon-Cept thus makes daily work easier and faster and helps avoid errors that occur by assembling wrong parts or by missing parts.

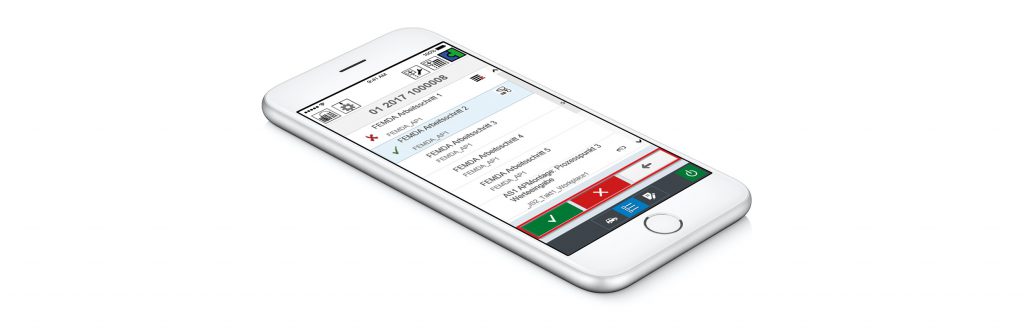

Electronic quality control loops

Electronic quality control loops are based on electronic documentations of the assembly status in the line. They contain all test results, variable process data and errors. This equates to an electronic checklist. The build documentation provided by MMS by Kon-Cept is used for controlling and managing the rework, test lines, audits, the yard, certification and shipping of products and guarantees that the quality of the products is documented fully at the time of shipping.

Electronic quality documentation

The electronic checklist records the quality status of a vehicle or product at each work place in the line and thus replaces the paper version of the checklist. MMS by Kon-Cept provides a sign-off mask that is the dedicated user interface for the worker.

JIS Logistics

Parts that come in a number of variants are delivered to the line as baskets and sequence carriers that are filled according to the production sequence of the products – this is called „just in sequence“. MMS by Kon-Cept implements electronic processes for picking in the supermarket and for managing routes. Together, this helps to avoid errors in the logistics process, makes the process more efficient and faster and reduces the inventory both in the supermarket and in the line.

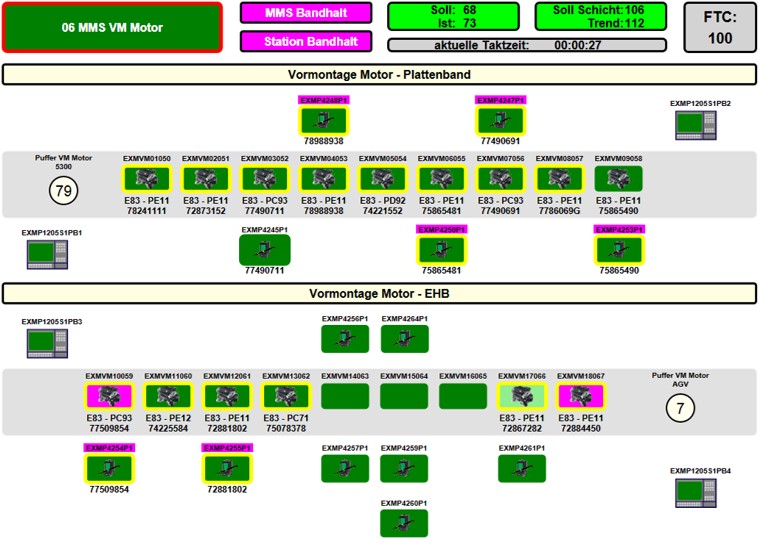

Acquisition of operational data

Conveyor systems and all production plants report their operation mode, part status and any errors to MMS by Kon-Cept whenever changes occur. MMS by Kon-Cept in turn monitors the production of downstream functions for alarms, reporting and maintenance. MMS by Kon-Cept immediately shows deviations and errors in the process – this allows us to promptly remedy the errors, thereby significantly reducing standstills and faulty products.

Controlling automated production plants

MMS by Kon-Cept offers a variety of functions for controlling automated production plants that range from EC nutrunners to filling stations and test stands and from storage systems to electronics test equipment. Work plans are managed centrally, and interfaces are designed uniformly. This results in a seamless documentation of the entire assembly process and allows for the immediate remedy of errors. Thus automatic process steps become transparent and traceable. Changes in line balancing as well as the product itself can be made and used directly.

Final treatment

Finished products leaving the line very often have a long way to go until they are ready for shipping. MMS by Kon-Cept controls and manages many processes in this area, such as rework, yard management, audits and tests, packing, certification and shipping. MMS by Kon-Cept takes care that processes like these run efficiently and that idle times, e.g. for searching for products, can be avoided. MMS by Kon-Cept helps you to reduce processing times and to increase delivery reliability.